The Pros and Cons of Upgrading Your Well Pump Controller

For well owners, the well pump controller is a critical component of their water system, managing the flow of water from the aquifer to the household. As technology advances, upgrading an outdated controller to a modern, smart, or automated system can significantly enhance well performance, especially for low-yielding wells. However, the decision to upgrade involves weighing potential benefits against costs and complexities. With well drilling costs ranging from $3,000 to $15,000 for a new well, upgrading a controller often presents a more affordable alternative to improve water delivery without major infrastructure changes. This article explores the advantages and drawbacks of upgrading your well pump controller, offering insights to help well owners make informed decisions.

Understanding the Role of a Well Pump Controller

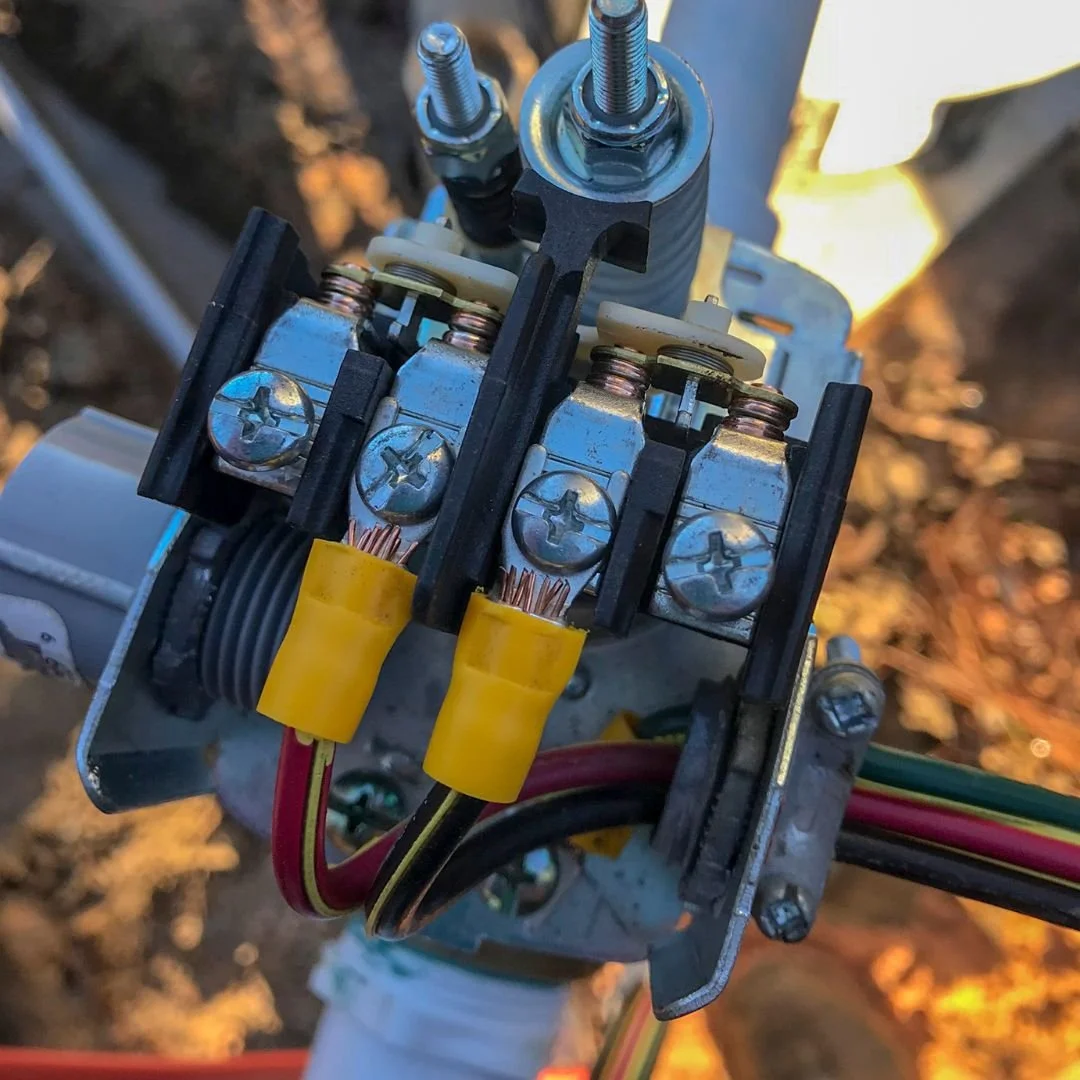

A well pump controller regulates the operation of the pump, ensuring water is drawn from the well efficiently and delivered at consistent pressure. Traditional controllers, such as pressure switches or basic timers, turn the pump on and off based on simple triggers like tank pressure or time intervals. These older systems, while reliable, often lack precision, leading to over-pumping, inconsistent pressure, or excessive wear on the pump. Modern controllers, by contrast, incorporate advanced features like variable-speed drives, real-time monitoring, and automated adjustments, tailoring water draw to the well’s capacity and household demand.

Upgrading a controller can transform how a well operates, particularly for homes with low-yielding wells that struggle to meet peak usage needs, such as simultaneous showers and laundry. However, the process requires careful consideration of costs, compatibility, and maintenance needs. Below, we examine the pros and cons of upgrading to help well owners decide if it’s the right move for their system.

Pros of Upgrading Your Well Pump Controller

Enhanced Efficiency and Pump Longevity

Modern well pump controllers, such as those with variable-speed technology, adjust the pump’s operation to match real-time demand, reducing unnecessary cycling. Traditional controllers often run the pump at full capacity regardless of need, leading to energy waste and wear on components. By optimizing pump activity, upgraded controllers can lower electricity costs and extend the pump’s lifespan, which typically ranges from 10 to 15 years. For example, a variable-speed controller might reduce energy consumption by up to 30%, saving money and reducing the risk of costly pump replacements.

Improved Water Pressure and Consistency

Older controllers, like basic pressure switches, can result in fluctuating water pressure, causing weak showers or sputtering faucets. Upgraded controllers maintain steady pressure, often between 40-60 psi, by dynamically adjusting pump speed. This ensures a smooth water flow, even during high-demand periods, enhancing the user experience for households accustomed to inconsistent delivery. For tiny homes or properties with multiple appliances, this consistency can make a significant difference in daily comfort.

Protection Against Over-Pumping

Low-yielding wells are particularly vulnerable to over-pumping, which can deplete the aquifer or damage the pump by running it dry. Advanced controllers incorporate features like low-water cutoff sensors or automated draw adjustments, shutting off the pump when water levels are too low. This protects both the well and the pump, preserving the aquifer’s sustainability and preventing costly repairs. For well owners in drought-prone areas, this feature is critical for long-term water security.

Real-Time Monitoring and Control

Modern controllers often include digital interfaces or mobile apps, allowing owners to monitor water usage, pressure, and pump status in real time. This visibility enables proactive management, such as detecting leaks or identifying when maintenance is needed. For example, a smart controller might alert you to a drop in well output, prompting adjustments before the system fails. This level of control is especially valuable for remote properties or busy households, reducing the need for manual checks.

Integration with Modern Systems

Upgrading a controller opens the door to integration with advanced water management systems, such as modular storage solutions or smart home setups. For instance, a new controller can work seamlessly with storage tanks to optimize water delivery, ensuring a reserve is available during peak demand. This compatibility enhances the overall efficiency of the water system, making it easier to adapt to changing needs, such as adding irrigation or supporting a growing household.

Cons of Upgrading Your Well Pump Controller

Initial Cost and Installation

The most significant drawback of upgrading a well pump controller is the upfront cost. While far less expensive than the well drilling cost, a modern controller, such as a variable-speed model, can range from $500 to $2,000, depending on features and compatibility. Installation may require professional expertise, especially if rewiring or system integration is needed, adding to the expense. For budget-conscious well owners, this initial investment may feel steep, particularly if the existing controller is still functional.

Compatibility Challenges

Not all wells or pumps are compatible with modern controllers. Older pumps may lack the necessary wiring or motor type to support variable-speed technology, requiring additional upgrades or replacements. For example, a submersible pump designed for a basic pressure switch may not work with a smart controller without modifications. Assessing compatibility before upgrading is crucial to avoid unexpected costs or system downtime.

Learning Curve and Maintenance

Advanced controllers often come with digital interfaces or programmable settings, which can be daunting for owners accustomed to simple systems. Learning to use features like real-time monitoring or adjusting pump parameters may require time and technical know-how. Additionally, while modern controllers are generally low-maintenance, their complex electronics may need occasional professional servicing, unlike basic switches that require minimal upkeep. For hands-off owners, this added complexity could be a drawback.

Potential Over-Reliance on Technology

Smart controllers rely on electronics, sensors, and sometimes internet connectivity, making them vulnerable to power outages or technical failures. In remote areas with unreliable power, a sophisticated controller may falter without a backup system, leaving the household without water. Traditional controllers, while less efficient, are often more robust in such conditions. Well owners must weigh the benefits of advanced features against the risks of technological dependence.

The Well Harvester

The Well Harvester from Epp Well Solutions enhances the benefits of an upgraded well pump controller, particularly for low-yielding wells. This modular water storage system has a built-in modern well pump controller, automatically adjusting water draw to prevent over-pumping while maintaining a steady supply. Its compact design uses real-time data to optimize water delivery based on the well’s capacity and household needs. For example, the Well Harvester can store water during low-demand periods, ensuring availability even if the controller detects low well output.

The system’s scalability allows owners to expand storage without major modifications, complementing a controller’s ability to manage fluctuating demands. Its user-friendly interface aligns with the monitoring capabilities of advanced controllers, providing a cohesive water management solution. For well owners upgrading their controller, the Well Harvester amplifies efficiency and reliability, offering a cost-effective alternative to drilling a new well while addressing low-yield challenges.

Practical Considerations for Upgrading

Before upgrading your well pump controller, consider these factors to ensure a successful transition:

Assess Your Well’s Needs: Evaluate your well’s yield, household demand, and existing pump to determine if an upgrade will address specific issues like low pressure or over-pumping.

Check Compatibility: Confirm that your pump and electrical system support the new controller, consulting a professional if needed.

Budget for Costs: Factor in the controller, installation, and potential pump upgrades, comparing these to long-term savings on energy and maintenance.

Choose Features Wisely: Select a controller with features that match your needs, such as variable-speed for efficiency or smart monitoring for remote management.

Plan for Backup Power: In areas with frequent outages, consider a generator or battery backup to ensure the controller remains operational.

These steps help align the upgrade with your well’s unique requirements, maximizing benefits while minimizing drawbacks.

Long-Term Value of Upgrading

Upgrading a well pump controller offers long-term value by improving efficiency, protecting the well, and enhancing water delivery. While the initial cost and complexity may deter some owners, the savings on energy, pump maintenance, and potential well repairs often outweigh these concerns. For low-yielding wells, pairing an upgraded controller with a system like the Well Harvester can further optimize performance, avoiding the high well drilling cost while ensuring a reliable supply. This combination creates a modern, sustainable water system tailored to the needs of today’s well owners.

Upgrading your well pump controller presents a compelling opportunity to enhance your water system’s efficiency, reliability, and user experience. The benefits—improved pressure, pump protection, and smart monitoring—can transform how your well performs, particularly for low-yielding systems. However, the costs, compatibility issues, and technological complexity require careful consideration to ensure the upgrade aligns with your needs and budget. The Well Harvester from Epp Well Solutions complements these upgrades, offering a modular, automated solution that maximizes water availability in a compact package. For well owners seeking to modernize their system without the expense of a new well, upgrading the controller, paired with innovative tools, provides a path to consistent, worry-free water access.